Overview

Chronic diabetic wounds are one of several common complications of diabetes, manifested by extensive wound ulceration, persistent infection, and nerve damage, especially in the feet, and in severe cases, amputation. People with diabetes have a 15-20 times higher risk of amputation than normal people. Fortunately, 85% of amputations are accessible due to the early onset of symptoms. It is important to promote early healing of diabetic wounds. That's why we designed a new portable wound protector that combines our engineered algae to protect diabetic wounds and promote healing.

Based on the sterile environment of the wound, we designed the dressing to ensure the sterile environment, and added a protective gear to detect the wound in real time. Since it is mainly aimed at the elderly group, the feedback mechanism uses intuitive protective gear light changes and alarm sounds to keep patients informed of the wound situation.

Design

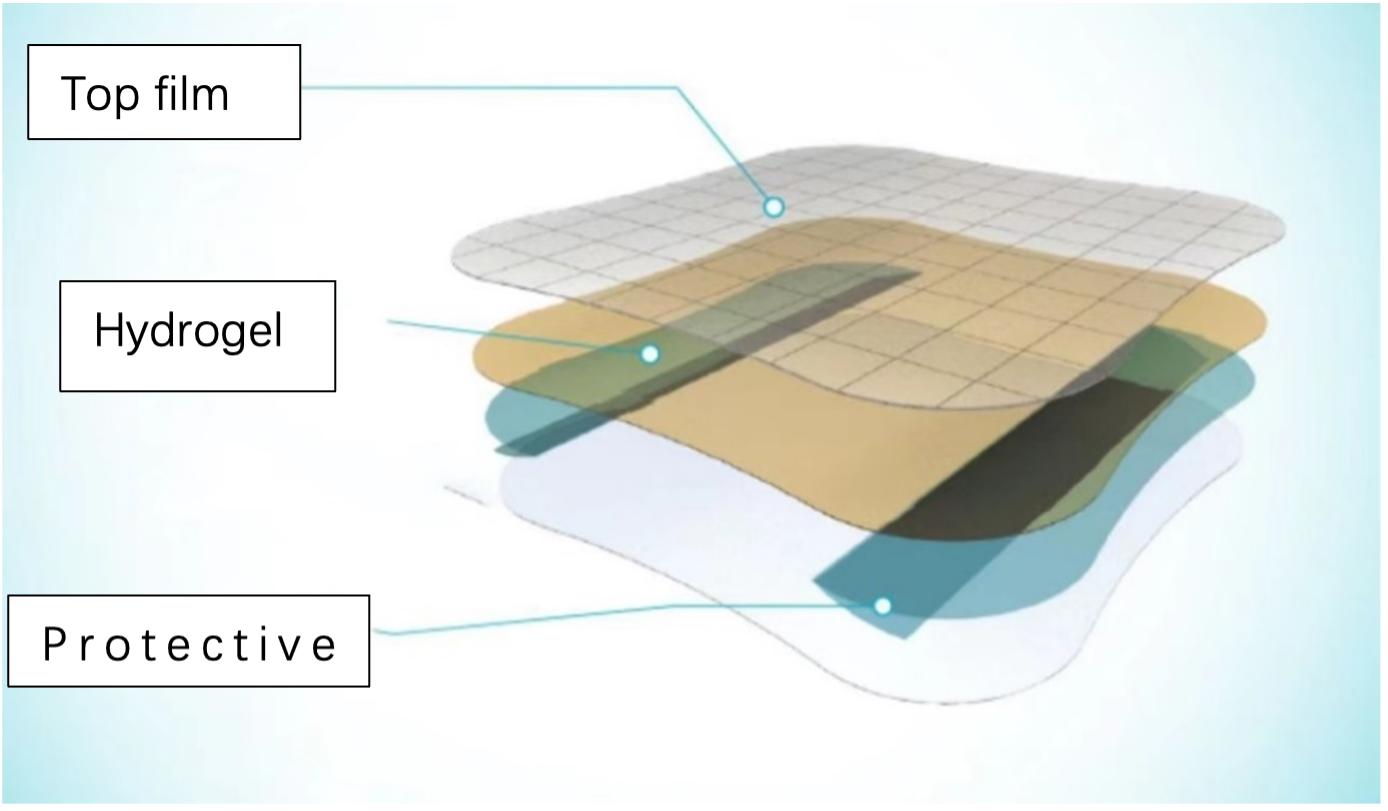

Dressing

Part I: Top Film

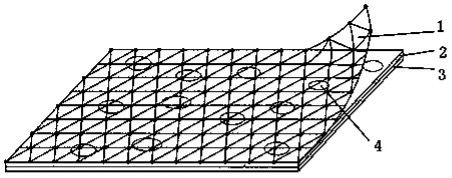

Material: anti-fouling and sterilization bifunctional polypropylene non-woven fabric (P non-woven fabric).

PP non-woven fabric has the advantages of good air permeability, excellent stability and low price, and is a kind of medical dressing with more applications. However, in a physiological environment, hydrophobic PP surfaces readily trigger bacterial adhesion and subsequent biofilm formation. To solve this problem, we co-deposit dopamine/polyvinylpyrrolidone (PDA/PVP) on the surface of the nonwoven. Because PDA has excellent bio-adhesion and can form a strong hydrogen bond with PVP, the resulting coating is firm. Subsequently, the terminal aminopolyethylene glycol (PEG-NH2) was used to react with the PDA Schiff base or Michael addition to introduce the antifouling PEG group to the surface of the coating, which gave the coating excellent anti-bacterial adhesion properties. In order to obtain better antibacterial performance, PVP and iodine (I2) in the coating were complexed to form a PVP-I complex, and the I2 bactericidal group was introduced to construct a PP non-woven surface with anti-fouling and bactericidal synergy.

Part II: Hydrogel dressings

Hydrogel material: polyvinyl alcohol / hemoglobin and silk fibroin hydrogel + antimicrobial peptides.

Oxygen Supply:

Silk oxygenated hydrogel, in which hemoglobin has peroxidase characteristics, can catalyze the tyrosine formation of silk fibroin enzyme cross-linked hydrogel, in the preparation process to produce oxygen, enzyme cross-linked hydrogel pore size, so that the prepared SF/Hb gel forms a three-dimensional pore structure, greatly increases the specific surface area, has a good oxygen-holding capacity, so that the gel slowly releases oxygen during use, increases the local oxygen content of chronic wounds, and effectively inhibits the table of hypoxia-inducible factors Reach, and is conducive to gas exchange, improving air permeability, inhibition of inflammation function, can be used as a wound dressing for various refractory wounds; In addition, by boiling silkworm cocoons at 98°C for 1h and repeating twice for degumming in the silkworm fibroin extraction stage, the β-folding of silkworm fibroin was reduced. Then, dialysis with boric acid buffer was added to further reduce the β-folding of silk fibroin solution, avoid gelation of silk fibroin solution, and increase the stability of silk fibroin solution, so as to obtain stable target concentration of silk fibroin aqueous solution at low temperature concentration, so as to improve the degree of crosslinking and significantly improve the mechanical strength of the gel.

Biocompatibility:

The in vitro cytotoxicity, intradermal reaction and delayed hypersensitivity of polyvinyl alcohol hydrogel material prepared by physical crosslinking method all meet the requirements of the national standard, and the material has good biocompatibility and is safe and reliable as a non-implantable medical material.

Added Substances:

Chlamydomonas reinthinein culture solution (TAP medium), yeast culture medium, D-fluorescein, antimicrobial peptide.

Cell Fixation:

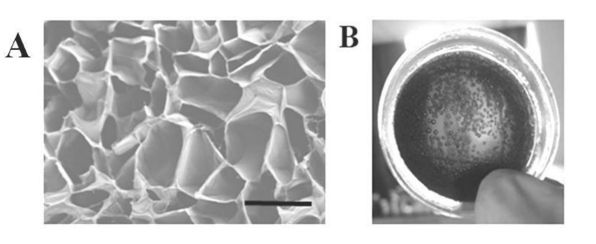

The enzyme-crosslinked hydrogel has a large pore size, so that the prepared SF/Hb gel forms a three-dimensional pore structure.

It is better to evenly distribute and fix the cells in the gel.

Preparation Method:

Physical cross-linking method: take 2% hemoglobin aqueous solution and 10% silk fibroin aqueous solution, mix hemoglobin aqueous solution and silk fibroin aqueous solution according to the volume ratio of 1:2, add hydrogen peroxide to a final concentration of 10mm, and form SF/HB oxygenated hydrogel. It is then mixed with polyvinyl alcohol, repeatedly frozen and thawed to complete the crosslinking, and finally form the desired composite hydrogel. At this time, the gel is in a liquid state, and the required antibacterial peptides, Chlamydomonas reinhardi and other substances can be added, and a colloidal substance can be formed by standing.

Part III: Protective Film

Composite porous lightweight and strong absorbent medical absorbent pad, when using superabsorbent materials, has strong water absorption, the water absorption is more than 10 times that of ordinary medical absorbent pads, and the anti-adhesion layer can prevent the absorbent pad from being in contact with the skin for a long time and thus embedded in the wound, causing secondary injury; The setting of the breathable hole in the cotton core layer makes the absorbent cushion have excellent air permeability, reduces the contact area with the wound, and reduces the damage to the wound after the wound exudates after the wound accumulates, thereby reducing the pressure on the wound and accelerating the wound healing.

Ankle Brace

Ankle brace based modifications that generate light sources and monitor dressing color changes in real time (brace modifications for other parts of the body will follow)

Light Source

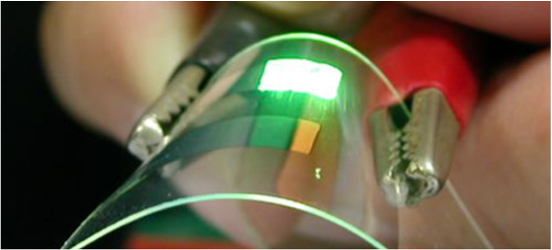

Flexible OLED:

Flexible OLED is implanted in a protective device to provide the light conditions required for photosynthesis (normal white light is sufficient) for Chlamydomonas reinininensis

Principle:

Power Supply:

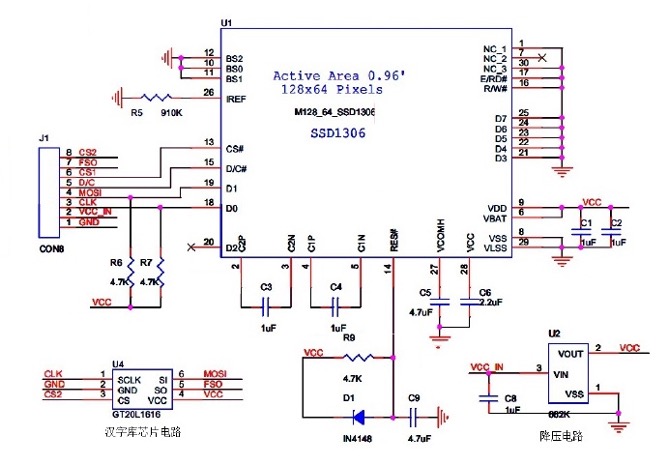

External rechargeable power supply (power component diagram omitted here), the power supply input of the module is VCC_IN, and it is fed to U1, U4 and other circuits after being stepped down by U2. The OLED screen driver requires a voltage of 7-7.5V and is boosted by the SSD1306's built-in charge pump.

Interface:

SSD1306 supports parallel, SPI and I2C and other serial protocols, this module through BS0-BS2 these three pins grounded, has been set as SPI protocol, and U4 Chinese font library chip share SPI interface, work through the chip selection pin to distinguish, read and write should be the target chip CS pin low level.

Other Peripheral Circuits:

R5=910K, set the constant current source reference current; R6 and R7 are pull-in resistors on the data line; RES# is connected to the reset circuit, and other circuits can be found in the driver chip data sheet.

Color Sensor

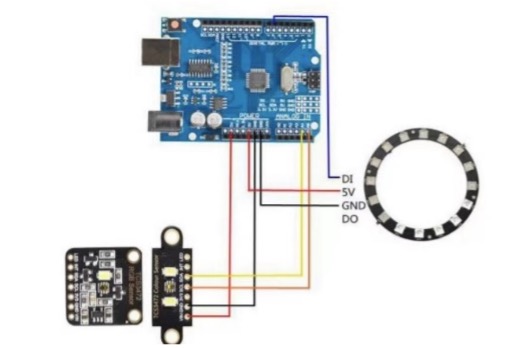

After the dressing treatment, the hydrogel will change from green to yellow. Color recognition sensors recognize colors, convert color signals into digital signals, and feedback devices emit the same light to alert the patient to the end of treatment.

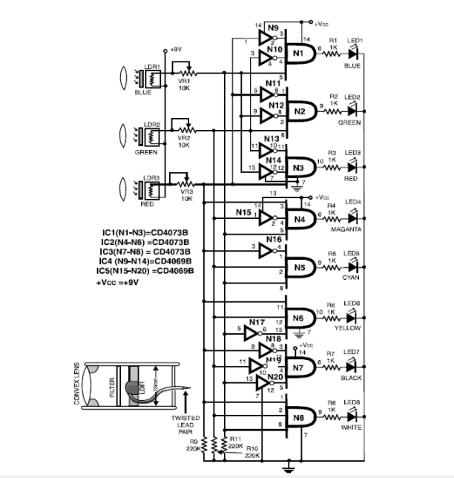

Principle:

The object that needs to detect color should be placed in front of the circuit/sensor. The light reflected from the object falls on the three convex lenses mounted in front of the three LDRs. Convex lenses are used to concentrate light. This helps to improve the sensitivity of the LDR, and the blue-green-red glass plates (filters) are fixed in front of LDR1, LDR2, and LDR3, respectively. When the reflected light from the object falls on the device, the colored filter glass plate decides which LDR will be triggered. The circuit uses only AND and NOT gates.

When primary color light falls on the system, a glass plate corresponding to that primary color will allow specific light to pass through. However, the other two glass plates do not allow any light to pass through. Therefore, only one specific LDR will be triggered, and the gate output corresponding to that LDR will change to a logic 1 to indicate which color it can be.

Similarly, when a second color light falls on the system, two primary color glass plates corresponding to the mixed color will allow that light to pass through, while the remaining glass plate will not allow any light to pass through it. As a result, two LDRs are triggered, and the gate outputs corresponding to these become logic 1s and indicate which color it really is.

Feedback Part:

Receives signals from color recognition sensors and converts them into optical signals:

- If the wound is normal, it is reported as white light, and if infection occurs, it is reported as yellow light.

- If infection occurs, the buzzer operates and sounds an alarm.

How to Use

The dressing is applied to the wound first, and then the ankle or other areas are wrapped with a protective gear. The feedback site flashes green at the initial state, white if no infection occurs at the end of treatment, and yellow light if infection occurs. If infection occurs, the buzzer operates at the same time to sound an alarm. The patient can change the dressing by removing the brace.